The simple guide for how to create custom stickers.

Our team loves covering everything in stickers to upgrade our computers, make our diaries ours, show off our cars and to add personality. However not all stickers are equal and have you ever wondered how they are made?

Follow the Yourstuffmade simple guide below to help you get some created. This guide is not supposed to stress you out as we are always here to help set-up your design and you will get a proof of concept before every order to make sure the product is what you imagine.

After carefully designing and deciding what sticker you want to create, this is probably the most important steps in the process as it impacts everything that follows.

Key things that happen at this stage:

- Drawing cutlines

- Adding bleeds (unprinted area of a design that allows for margin)

- Inputting registration marks to ensure they’re cut accurately

- Adjust colours to CMYK to ensure they print accurately

- Nest the artwork to be the most efficient use of space on the vinyl

- Export in the correct image format (.pdf, .png. ai., .jpeg etc)

Below are just a few great basic and professional design programs to help you create/design your own stickers, discover the one that fits your budget and style. If you're nervous? Our team of artist are more than happy for free to convert files into something that can be used for your stickers or give advice, just contact us.

- Free photo editor by Pixlr

- Easy background removal by Clipping Magic (popular)

- Vectorise by Vector Magic

- Edit vector images by Vecteezy

- Canva suite (popular)

- Coraldraw suite (popular)

- Illustrator (Apple iPad) Illustrator (PC) by Adobe (popular)

- Photoshop (Apple iPad) Photoshop (PC) by Adobe

- Procreate by Savage (Apple iPad) (popular)

Step 2- Printing

There are many different ways of printing and many different materials that can be printed on.

We start by taking rolls of print media (usually a plastic such as PVC or PET), and load it into our professional printers. Our printers are capable of applying a layer of ink about 15 microns thin and print up to 1440 DPI (dots per inch), which is incredibly small and ultra-high-resolution to create amazingly vibrant images.

The ink is then cured and this happens in different ways depending on the technology:

- UK inkjet uses UV light to instantly cure the ink

- Solvent inkjet – allow the solvent to ‘de-gas’ over time, usually 24 hours.

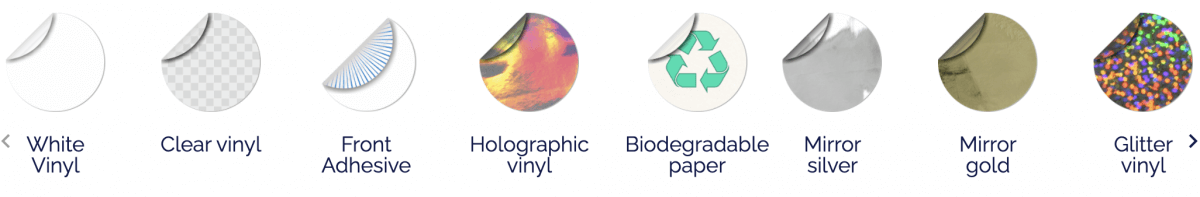

See some of our material options to below (contact us to find request any a specific material):

Step 3- Laminating

For some of our custom stickers, we apply a clear, protective layer to maximise the durability. There are many options that can be chosen but it’s really important they are compatible with the printable media and the print technology.

Laminates can be gloss, or matte, textured. Often the effect you choose can be personal preference, dependant on the effect you want to create. Adding a laminate protects the printed layer giving it resistance to sunlight, scratching, chemicals, oils and most other things that can ruin a sticker. It’s a really effective method of protection.

Step 4- Cutting

The final step we take before delivery is to cut it into your desired shape. The shape can be as complex as you want however the more tiny details you have the more small edges there are to lift. Chose from a basis shape (circle, rectangle etc) or a custom (die-cut) shape that outlines your design perfectly.

Our factory uses the latest machines that use a digitally controlled knives or high-speed lasers to cut stickers to speed up the process, reduce costs, increase accuracy and to avoid waste. Our stickers are made to be more accurate, quicker and cheaper, so you get your stickers fast!

Our team is so excited to work with you! Want to know more? contact us below

•Email • Instagram • Book a chat • Facebook